-

E-elevatorshop

-

31/05/2023

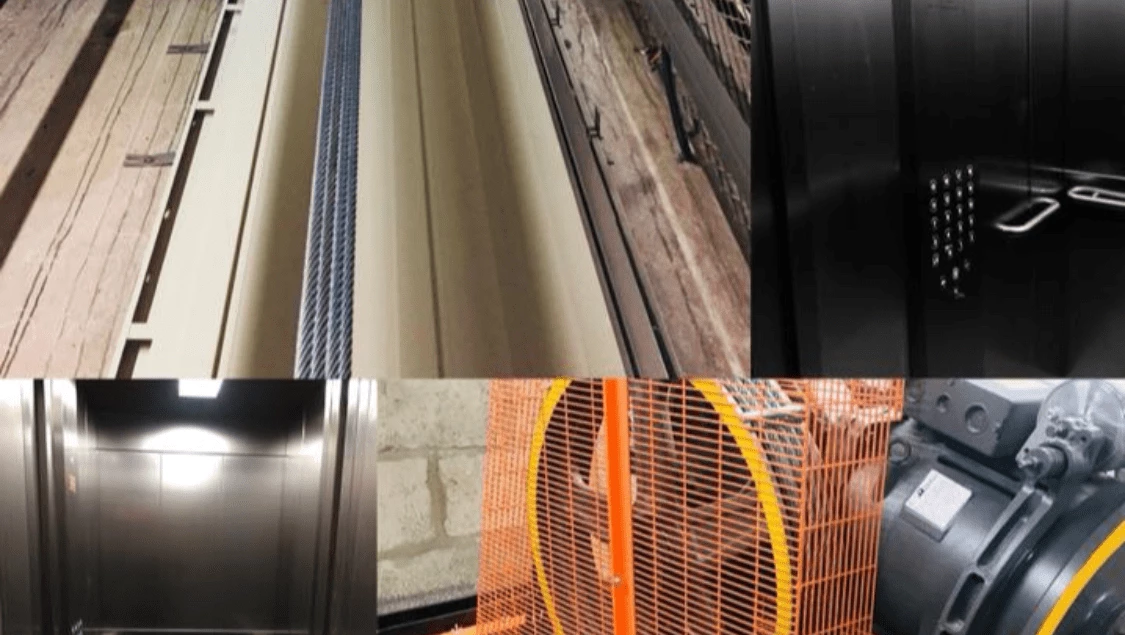

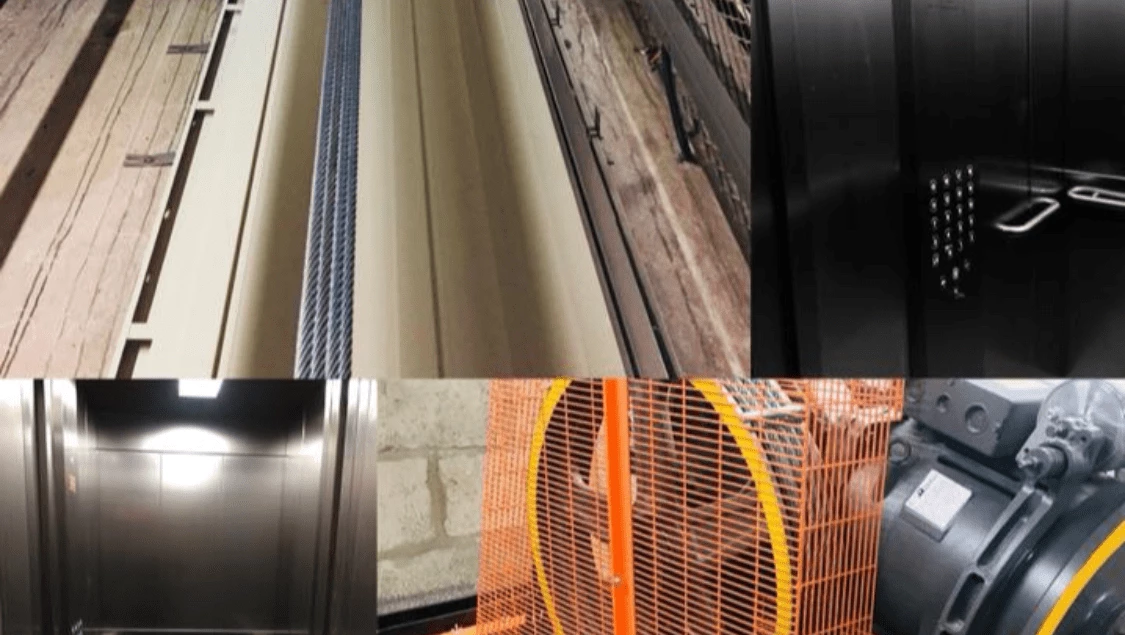

Elevators have become an integral part of our daily lives, transporting us swiftly and safely to different floors of buildings. Behind the scenes, there's an entire industry dedicated to manufacturing and maintaining these vertical transport systems. In an elevator shop, the presence of specific materials is crucial to ensure efficient operation, reliability, and, most importantly, the safety of passengers. In this article, we will explore the essential materials that should exist in an elevator shop, highlighting their significance in keeping elevators running smoothly and securely.

-

High-Quality Elevator Cables: At the heart of every elevator, there's a sturdy set of cables responsible for supporting the cab and its occupants. These cables, typically made of high-strength steel, provide the tensile strength necessary to bear the weight of the elevator car. It's imperative for an elevator shop to stock durable and reliable elevator cables, ensuring their compliance with stringent safety standards.

-

Control Panels and Electrical Components: Elevators rely on a sophisticated network of electrical components and control systems to operate smoothly. The elevator shop must maintain a stock of control panels, circuit boards, relays, and other critical electrical components. These materials enable the proper functioning of the elevator's motor, brake systems, emergency stop buttons, and other safety features.

-

Safety Devices and Sensors: Safety is paramount in any elevator system, and the elevator shop should prioritize the availability of various safety devices and sensors. These materials include overspeed governors, which activate the brakes if the elevator moves too quickly, and limit switches that ensure the car aligns correctly with the floors. Additionally, infrared or laser-based door sensors are crucial for preventing door-closing accidents and ensuring passenger safety.

-

Fire-Resistant Materials: In the unfortunate event of a fire, elevators need to be equipped with fire-resistant materials to prevent the spread of flames and smoke. The elevator shop should provide fire-rated doors, fire-resistant cables, and fireproof panels for elevator shafts. These materials contribute significantly to the overall fire safety of buildings and enhance the evacuation process during emergencies.

-

Maintenance and Lubrication Supplies: To keep elevators running smoothly, regular maintenance and lubrication are vital. The elevator shop should offer lubricants specifically designed for elevator components, such as bearings, gears, and pulleys. Additionally, a comprehensive range of maintenance tools, such as multimeters, torque wrenches, and safety harnesses, should be available to facilitate routine inspections, repairs, and replacements.

-

Sustainable and Energy-Efficient Materials: In today's environmentally conscious world, elevator shops should also prioritize sustainable and energy-efficient materials. This includes LED lighting solutions for elevator cars and shafts, which consume less electricity and have longer lifespans. Furthermore, the shop should stock energy-efficient motors, regenerative drives, and other eco-friendly components to reduce the elevator's overall carbon footprint.

The materials found in an elevator shop play a critical role in maintaining the functionality, safety, and efficiency of elevator systems. From high-quality cables and electrical components to safety devices and fire-resistant materials, each item contributes to the overall reliability of elevators. Additionally, the inclusion of sustainable and energy-efficient materials demonstrates a commitment to reducing environmental impact. By prioritizing these essential materials, elevator shops ensure that our vertical transportation systems operate smoothly, providing a safe and reliable means of moving people within buildings.

Elevators have become an integral part of our daily lives, transporting us swiftly and safely to different floors of buildings. Behind the scenes, there's an entire industry dedicated to manufacturing and maintaining these vertical transport systems. In an elevator shop, the presence of specific materials is crucial to ensure efficient operation, reliability, and, most importantly, the safety of passengers. In this article, we will explore the essential materials that should exist in an elevator shop, highlighting their significance in keeping elevators running smoothly and securely.

Elevators have become an integral part of our daily lives, transporting us swiftly and safely to different floors of buildings. Behind the scenes, there's an entire industry dedicated to manufacturing and maintaining these vertical transport systems. In an elevator shop, the presence of specific materials is crucial to ensure efficient operation, reliability, and, most importantly, the safety of passengers. In this article, we will explore the essential materials that should exist in an elevator shop, highlighting their significance in keeping elevators running smoothly and securely.